| Availability: | |

|---|---|

| Quantity: | |

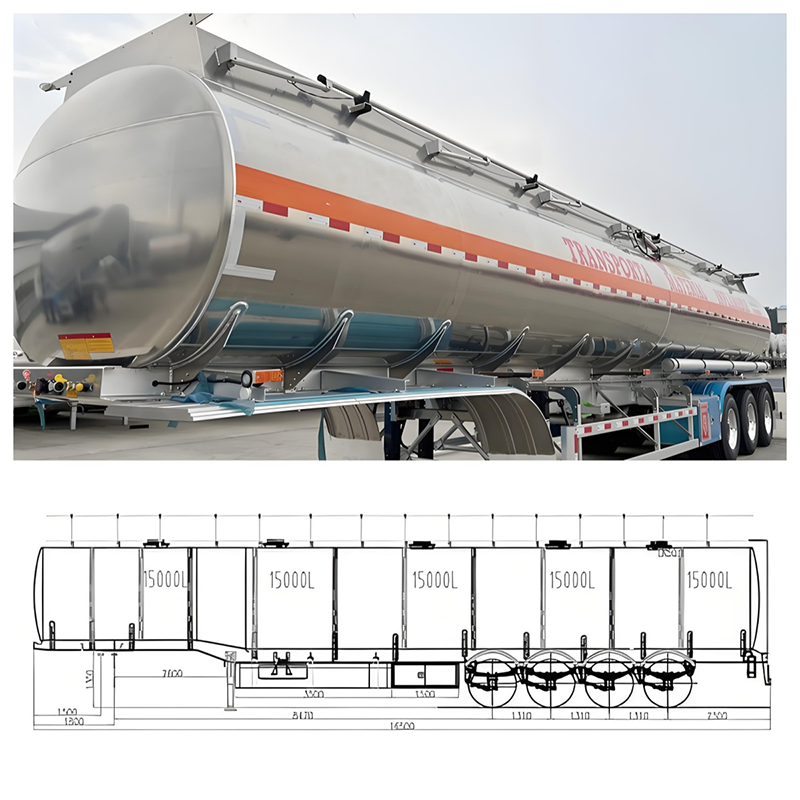

Aluminum Alloy Tanker Semi Trailers offer a high-performance solution for transporting a diverse range of liquid and food-grade products. Primarily constructed from marine-grade aluminum alloys like AA5083 and AA5454, these trailers combine significant weight savings with excellent corrosion resistance. This makes them ideal for food products, potable water, chemicals sensitive to contamination, and fuels where weight reduction is paramount. They meet stringent international standards (DOT407, TC, ADR, ECE R111).

Body designed with multi-channel wave-proof plate sto reduce the fluctuation during transportation.

Designed many compartments for different media transportation.

Adopt Heavy-duty landing gear supports the trailer when not connected to the tractor

Have air brakes connected to the tractor's braking system for safe stopping

Capacity | 3000 Liters |

Size | 10500*2500*3500mm |

Compartment | 2-8 Compartments |

Tank Body | Body: 3.5 mm, Anti-surge plate: 3.0 mm, End plate: 4.0 mm, Material: Aluminum |

Axles | 3 Axles*13/16Ton,FUWA/BPW or Customization |

Braking System | Air Dual braking system,with relay valve |

Landing gear | 28 Tons Two Speed,JOST/Other Brand |

Application | Fuel,Oil,Crude oil,diesel,petrol,gasoline |

Advanced Alloy Construction: AA5083/AA5454 alloys provide high strength-to-weight ratio and superior resistance to corrosion from various substances, including salt water and many chemicals.

Payload Optimization: Reduced tare weight compared to steel tankers directly translates to increased payload capacity and improved fuel efficiency for the tractor unit.

Hygienic & Non-Contaminating: Smooth, non-porous aluminum surfaces are easily cleaned and sanitized, making them suitable for food-grade (e.g., milk, juice, edible oils) and pharmaceutical liquids.

Design Versatility: Configured for multiple compartments, various valve systems (butterfly, ball), vapor recovery, bottom/top loading, and insulation for temperature-sensitive products.

Durability & Lifecycle: Resistant to corrosion fatigue, offering a potentially longer service life with lower maintenance costs than steel in many applications.

Q: Are aluminum tankers suitable for all chemicals?

A: While excellent for many, aluminum is not suitable for highly acidic (low pH) or highly alkaline (high pH) chemicals without specific alloy selection or internal linings. Compatibility must be verified per chemical.

Q: How does weight compare to a steel tanker?

A: An aluminum tanker can weigh 2,000-4,000 kg less than a comparable steel tanker, significantly increasing payload capacity within legal weight limits.

Q: Is special cleaning required for food-grade use?

A: Yes, food-grade applications require specific cleaning and sanitation protocols validated to food safety standards (e.g., FDA, EHEDG). The smooth aluminum surface facilitates this process.

Q: What are common compartment configurations?

A: Similar to other tankers, configurations range from single compartment to 5 or more compartments, tailored to the specific cargo requirements and regulations.

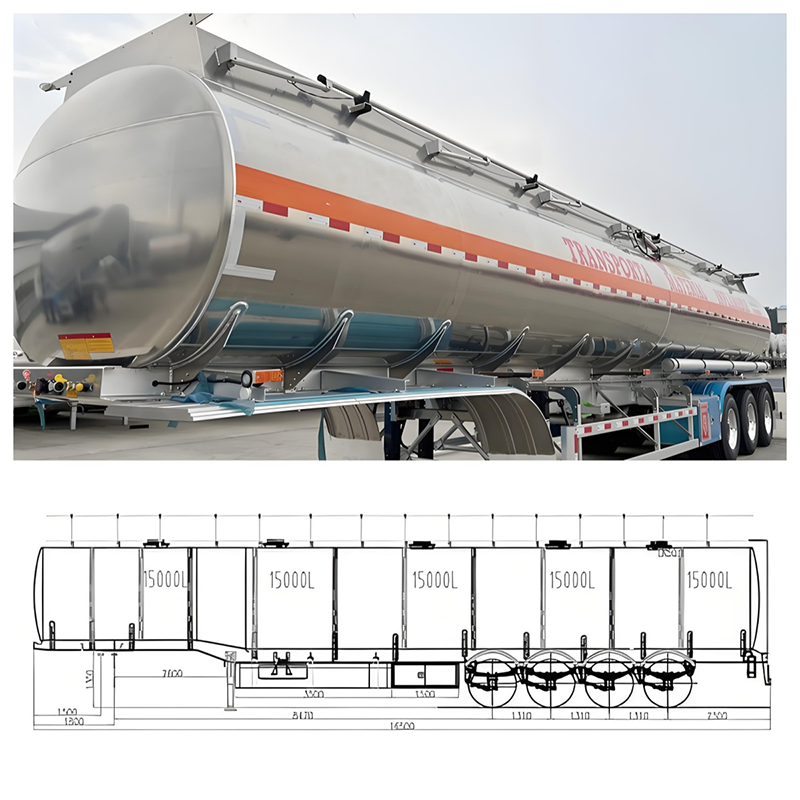

Aluminum Alloy Tanker Semi Trailers offer a high-performance solution for transporting a diverse range of liquid and food-grade products. Primarily constructed from marine-grade aluminum alloys like AA5083 and AA5454, these trailers combine significant weight savings with excellent corrosion resistance. This makes them ideal for food products, potable water, chemicals sensitive to contamination, and fuels where weight reduction is paramount. They meet stringent international standards (DOT407, TC, ADR, ECE R111).

Body designed with multi-channel wave-proof plate sto reduce the fluctuation during transportation.

Designed many compartments for different media transportation.

Adopt Heavy-duty landing gear supports the trailer when not connected to the tractor

Have air brakes connected to the tractor's braking system for safe stopping

Capacity | 3000 Liters |

Size | 10500*2500*3500mm |

Compartment | 2-8 Compartments |

Tank Body | Body: 3.5 mm, Anti-surge plate: 3.0 mm, End plate: 4.0 mm, Material: Aluminum |

Axles | 3 Axles*13/16Ton,FUWA/BPW or Customization |

Braking System | Air Dual braking system,with relay valve |

Landing gear | 28 Tons Two Speed,JOST/Other Brand |

Application | Fuel,Oil,Crude oil,diesel,petrol,gasoline |

Advanced Alloy Construction: AA5083/AA5454 alloys provide high strength-to-weight ratio and superior resistance to corrosion from various substances, including salt water and many chemicals.

Payload Optimization: Reduced tare weight compared to steel tankers directly translates to increased payload capacity and improved fuel efficiency for the tractor unit.

Hygienic & Non-Contaminating: Smooth, non-porous aluminum surfaces are easily cleaned and sanitized, making them suitable for food-grade (e.g., milk, juice, edible oils) and pharmaceutical liquids.

Design Versatility: Configured for multiple compartments, various valve systems (butterfly, ball), vapor recovery, bottom/top loading, and insulation for temperature-sensitive products.

Durability & Lifecycle: Resistant to corrosion fatigue, offering a potentially longer service life with lower maintenance costs than steel in many applications.

Q: Are aluminum tankers suitable for all chemicals?

A: While excellent for many, aluminum is not suitable for highly acidic (low pH) or highly alkaline (high pH) chemicals without specific alloy selection or internal linings. Compatibility must be verified per chemical.

Q: How does weight compare to a steel tanker?

A: An aluminum tanker can weigh 2,000-4,000 kg less than a comparable steel tanker, significantly increasing payload capacity within legal weight limits.

Q: Is special cleaning required for food-grade use?

A: Yes, food-grade applications require specific cleaning and sanitation protocols validated to food safety standards (e.g., FDA, EHEDG). The smooth aluminum surface facilitates this process.

Q: What are common compartment configurations?

A: Similar to other tankers, configurations range from single compartment to 5 or more compartments, tailored to the specific cargo requirements and regulations.