| Availability: | |

|---|---|

| Quantity: | |

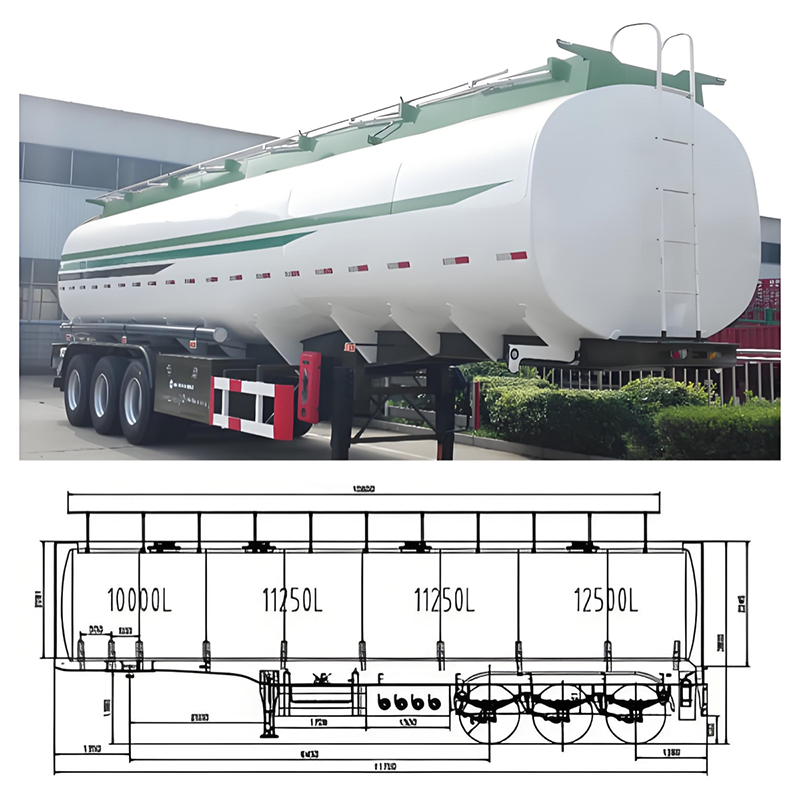

The Fuel Oil Tanker Semi Trailer is a specialized vehicle designed for the transportation of various types of fuel oils, including diesel, gasoline, and heating oil. It consists of a large cylindrical tank mounted on a semi-trailer chassis, which is towed by a tractor unit. This type of trailer is essential for the distribution of fuel from refineries to gas stations, industrial facilities, and other end-users. It is built with strict safety standards in mind to prevent leaks and ensure the safe transportation of flammable liquids. The design of the tank and associated components is optimized for efficient loading, unloading, and transportation of fuel oils.

High-Capacity Tank: The tank is available in various capacities, typically ranging from 20,000 to 50,000 liters, allowing for large-volume transportation of fuel oils.

Material Construction: The tank is made from high-quality carbon steel or aluminum alloy, which offers good corrosion resistance and strength to withstand the pressure of the fuel.

Safety Valves and Fittings: Equipped with multiple safety valves, including pressure relief valves and emergency shut-off valves, to prevent overpressure and leaks in case of an emergency.

Loading and Unloading Systems: Features a pumping system and hoses for efficient loading and unloading of fuel, with controls located in a safe and accessible position.

Anti-Sloshing Design: The tank interior may have baffles to reduce fuel sloshing during transportation, which helps improve stability and reduce stress on the tank structure.

Grounding System: Includes a grounding cable to prevent static electricity buildup, which can be a fire hazard when handling flammable fuels.

Semi Trailer Type | Fuel Oil Tanker Semi Trailer |

Capacity | 4500 Liters |

Fuel Tanker Trailer Size | 11500*2500*3500mm |

Compartment | 6 Compartments |

Tank Body | Body: 3.5 mm, Anti-surge plate: 3.0 mm, End plate: 4.0 mm, Material: 304 Carbon steel |

Axles | 3 Axles*13/16Ton,FUWA/BPW or Customization |

Braking System | Air Dual braking system,with relay valve |

Suspension | Heavy duty mechanical suspension / Air bag / Bogies |

Landing gear | 28 Tons Two Speed,JOST/Other Brand |

Tire | 12R22.5 (8/12 Pieces) Linglong/Triangle/Double-Coin/Bridgestone/Other |

Application | Fuel,Oil,Crude oil,diesel,petrol,gasoline |

Efficient Fuel Distribution: The large capacity and efficient loading/unloading systems enable quick and convenient distribution of fuel, reducing the number of trips required and improving operational efficiency.

Safety Assurance: Strict adherence to safety standards and the presence of multiple safety features minimize the risk of accidents, leaks, and fires, ensuring the safe transportation of fuel.

Durability: The high-quality materials and robust construction ensure a long service life, even with frequent use and exposure to harsh conditions.

Versatility: Can be used to transport different types of fuel oils, making it a flexible option for fuel distributors with diverse product lines.

Regulatory Compliance: Designed to meet international and national regulations regarding the transportation of hazardous materials, ensuring legal compliance for operators.

Q: What types of fuel oils can be transported in this tanker semi trailer?

A: It can transport a variety of fuel oils, including diesel, gasoline, kerosene, and heating oil, depending on the specific design and certifications.

Q: How is the fuel tanker semi trailer cleaned and maintained?

A: Regular cleaning is necessary to prevent contamination of different fuel types. Maintenance includes inspections of the tank, valves, pumping system, and safety components, with repairs or replacements as needed.

Q: What safety precautions are taken during transportation?

A: Drivers must follow strict safety protocols, including proper grounding before loading/unloading, avoiding smoking and open flames near the trailer, and adhering to speed limits and traffic rules. The trailer also has reflective markings for visibility.

Q: What is the maximum weight of the loaded tanker semi trailer?

A: The maximum weight depends on the trailer's design and local regulations, but it typically ranges from 30 to 40 tons when fully loaded.

Q: Are there any special licenses or certifications required to operate a fuel oil tanker semi trailer?

A: Yes, drivers need a commercial driver's license (CDL) with a hazardous materials endorsement, and the trailer must meet specific safety certifications and inspections.

The Fuel Oil Tanker Semi Trailer is a specialized vehicle designed for the transportation of various types of fuel oils, including diesel, gasoline, and heating oil. It consists of a large cylindrical tank mounted on a semi-trailer chassis, which is towed by a tractor unit. This type of trailer is essential for the distribution of fuel from refineries to gas stations, industrial facilities, and other end-users. It is built with strict safety standards in mind to prevent leaks and ensure the safe transportation of flammable liquids. The design of the tank and associated components is optimized for efficient loading, unloading, and transportation of fuel oils.

High-Capacity Tank: The tank is available in various capacities, typically ranging from 20,000 to 50,000 liters, allowing for large-volume transportation of fuel oils.

Material Construction: The tank is made from high-quality carbon steel or aluminum alloy, which offers good corrosion resistance and strength to withstand the pressure of the fuel.

Safety Valves and Fittings: Equipped with multiple safety valves, including pressure relief valves and emergency shut-off valves, to prevent overpressure and leaks in case of an emergency.

Loading and Unloading Systems: Features a pumping system and hoses for efficient loading and unloading of fuel, with controls located in a safe and accessible position.

Anti-Sloshing Design: The tank interior may have baffles to reduce fuel sloshing during transportation, which helps improve stability and reduce stress on the tank structure.

Grounding System: Includes a grounding cable to prevent static electricity buildup, which can be a fire hazard when handling flammable fuels.

Semi Trailer Type | Fuel Oil Tanker Semi Trailer |

Capacity | 4500 Liters |

Fuel Tanker Trailer Size | 11500*2500*3500mm |

Compartment | 6 Compartments |

Tank Body | Body: 3.5 mm, Anti-surge plate: 3.0 mm, End plate: 4.0 mm, Material: 304 Carbon steel |

Axles | 3 Axles*13/16Ton,FUWA/BPW or Customization |

Braking System | Air Dual braking system,with relay valve |

Suspension | Heavy duty mechanical suspension / Air bag / Bogies |

Landing gear | 28 Tons Two Speed,JOST/Other Brand |

Tire | 12R22.5 (8/12 Pieces) Linglong/Triangle/Double-Coin/Bridgestone/Other |

Application | Fuel,Oil,Crude oil,diesel,petrol,gasoline |

Efficient Fuel Distribution: The large capacity and efficient loading/unloading systems enable quick and convenient distribution of fuel, reducing the number of trips required and improving operational efficiency.

Safety Assurance: Strict adherence to safety standards and the presence of multiple safety features minimize the risk of accidents, leaks, and fires, ensuring the safe transportation of fuel.

Durability: The high-quality materials and robust construction ensure a long service life, even with frequent use and exposure to harsh conditions.

Versatility: Can be used to transport different types of fuel oils, making it a flexible option for fuel distributors with diverse product lines.

Regulatory Compliance: Designed to meet international and national regulations regarding the transportation of hazardous materials, ensuring legal compliance for operators.

Q: What types of fuel oils can be transported in this tanker semi trailer?

A: It can transport a variety of fuel oils, including diesel, gasoline, kerosene, and heating oil, depending on the specific design and certifications.

Q: How is the fuel tanker semi trailer cleaned and maintained?

A: Regular cleaning is necessary to prevent contamination of different fuel types. Maintenance includes inspections of the tank, valves, pumping system, and safety components, with repairs or replacements as needed.

Q: What safety precautions are taken during transportation?

A: Drivers must follow strict safety protocols, including proper grounding before loading/unloading, avoiding smoking and open flames near the trailer, and adhering to speed limits and traffic rules. The trailer also has reflective markings for visibility.

Q: What is the maximum weight of the loaded tanker semi trailer?

A: The maximum weight depends on the trailer's design and local regulations, but it typically ranges from 30 to 40 tons when fully loaded.

Q: Are there any special licenses or certifications required to operate a fuel oil tanker semi trailer?

A: Yes, drivers need a commercial driver's license (CDL) with a hazardous materials endorsement, and the trailer must meet specific safety certifications and inspections.