| Availability: | |

|---|---|

| Quantity: | |

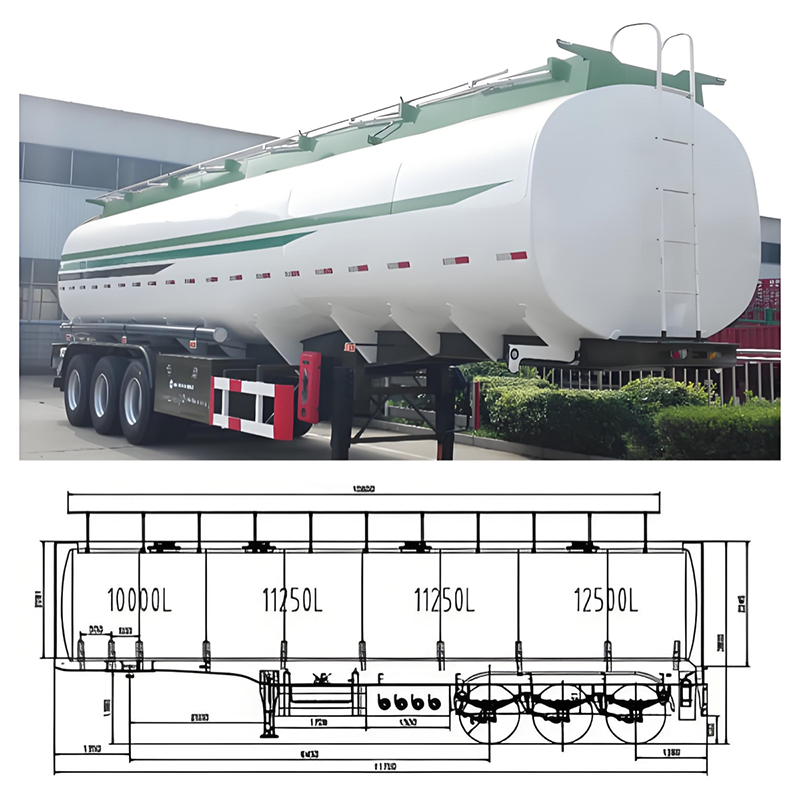

The Carbon Steel Oil Tanker Trailer is a workhorse designed for the reliable transportation of various petroleum products, including diesel, gasoline, and light fuel oils. Constructed predominantly from carbon steel, these trailers offer durability and cost-effectiveness for non-corrosive applications. They are engineered to comply with relevant transport regulations for flammable liquids, featuring essential safety systems and typically offering capacities ranging from 35,000 to 50,000 liters.

Tank Construction: Fabricated from carbon steel plate meeting specific thickness and quality standards (e.g., ASTM A516). The interior is often treated with coatings suitable for oil products to prevent rust and contamination.

Safety Systems: Includes bottom loading and discharge valves with emergency shut-off, vapor recovery systems, pressure/vacuum relief valves, spill containment, grounding cables, and fire suppression equipment mounts. Compliant with DOT 406 or similar standards.

Compartmentalization: Frequently divided into multiple compartments (e.g., 2-4) to allow transport of different grades of fuel simultaneously.

Subframe and Undercarriage: Heavy-duty steel subframe supports the tank. Equipped with reliable axles (air suspension common for stability), effective braking systems (ABS), and appropriate lighting.

Operational Components: Features manholes for inspection and cleaning, sight gauges for level checking (where permitted), and vapor-tight fittings.

Capacity | 4500 Liters |

Size | 13000*2500*3600mm |

Tank Body | Body: 3.5 mm, Anti-surge plate: 3.0 mm, End plate: 4.0 mm,Material: 304 Carbon steel |

Axles | 3 Axles*13/16Ton,FUWA/BPW |

Braking System | Air Dual braking system,with relay valve |

Suspension | Mechanical suspension or Air suspension |

Landing gear | Jost 28 Tons Two Speed |

Primarily utilized by fuel distribution companies, oil refineries, and commercial fueling operations. It transports gasoline, diesel fuel, kerosene, jet fuel (Jet-A), and other light petroleum distillates from terminals to service stations, commercial accounts, and airports.

Q: Is carbon steel suitable for all oil products?

A: Carbon steel is suitable for most standard petroleum distillates like gasoline and diesel. However, certain aggressive additives or biodiesel blends may require specific internal coatings or alternative materials like stainless steel.

Q: What vapor recovery systems are used?

A: Common systems include Balanced Pressure (Stage I) for loading at terminals and potentially Onboard (ORVR) systems for controlling vapors during vehicle refueling, depending on local regulations.

Q: How many compartments are typical?

A: 2 to 4 compartments are common, allowing distributors to carry different products (e.g., unleaded, premium, diesel) on a single run.

Q: What maintenance is critical?

A: Regular inspection for corrosion (external and internal), testing of safety valves and emergency shut-offs, integrity checks of grounding systems, and thorough cleaning schedules are essential.

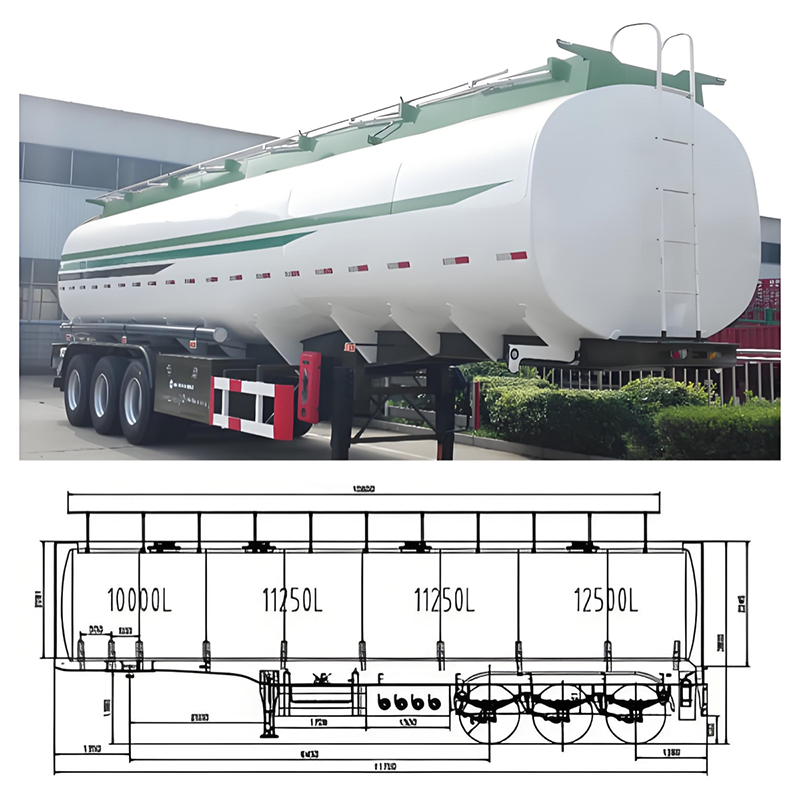

The Carbon Steel Oil Tanker Trailer is a workhorse designed for the reliable transportation of various petroleum products, including diesel, gasoline, and light fuel oils. Constructed predominantly from carbon steel, these trailers offer durability and cost-effectiveness for non-corrosive applications. They are engineered to comply with relevant transport regulations for flammable liquids, featuring essential safety systems and typically offering capacities ranging from 35,000 to 50,000 liters.

Tank Construction: Fabricated from carbon steel plate meeting specific thickness and quality standards (e.g., ASTM A516). The interior is often treated with coatings suitable for oil products to prevent rust and contamination.

Safety Systems: Includes bottom loading and discharge valves with emergency shut-off, vapor recovery systems, pressure/vacuum relief valves, spill containment, grounding cables, and fire suppression equipment mounts. Compliant with DOT 406 or similar standards.

Compartmentalization: Frequently divided into multiple compartments (e.g., 2-4) to allow transport of different grades of fuel simultaneously.

Subframe and Undercarriage: Heavy-duty steel subframe supports the tank. Equipped with reliable axles (air suspension common for stability), effective braking systems (ABS), and appropriate lighting.

Operational Components: Features manholes for inspection and cleaning, sight gauges for level checking (where permitted), and vapor-tight fittings.

Capacity | 4500 Liters |

Size | 13000*2500*3600mm |

Tank Body | Body: 3.5 mm, Anti-surge plate: 3.0 mm, End plate: 4.0 mm,Material: 304 Carbon steel |

Axles | 3 Axles*13/16Ton,FUWA/BPW |

Braking System | Air Dual braking system,with relay valve |

Suspension | Mechanical suspension or Air suspension |

Landing gear | Jost 28 Tons Two Speed |

Primarily utilized by fuel distribution companies, oil refineries, and commercial fueling operations. It transports gasoline, diesel fuel, kerosene, jet fuel (Jet-A), and other light petroleum distillates from terminals to service stations, commercial accounts, and airports.

Q: Is carbon steel suitable for all oil products?

A: Carbon steel is suitable for most standard petroleum distillates like gasoline and diesel. However, certain aggressive additives or biodiesel blends may require specific internal coatings or alternative materials like stainless steel.

Q: What vapor recovery systems are used?

A: Common systems include Balanced Pressure (Stage I) for loading at terminals and potentially Onboard (ORVR) systems for controlling vapors during vehicle refueling, depending on local regulations.

Q: How many compartments are typical?

A: 2 to 4 compartments are common, allowing distributors to carry different products (e.g., unleaded, premium, diesel) on a single run.

Q: What maintenance is critical?

A: Regular inspection for corrosion (external and internal), testing of safety valves and emergency shut-offs, integrity checks of grounding systems, and thorough cleaning schedules are essential.