| Availability: | |

|---|---|

| Quantity: | |

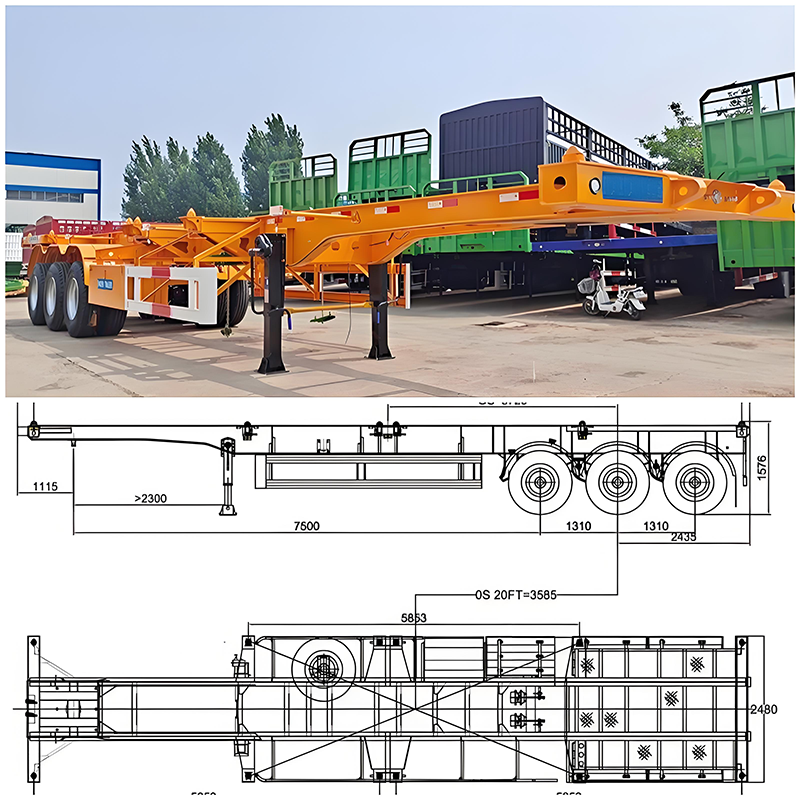

The Gooseneck Intermodal Skeleton Container Chassis is a specialized piece of transportation equipment engineered to facilitate the seamless movement of shipping containers across various intermodal transport networks. Its unique gooseneck design, which curves upward at the front, distinguishes it from other chassis types, allowing for optimal weight distribution and enhanced maneuverability. This chassis is widely utilized in ports, freight terminals, rail yards, and logistics centers, serving as a critical link in the global supply chain. It is compatible with standard shipping containers of multiple sizes, making it a versatile solution for businesses involved in international and domestic trade. Whether transporting containers via truck, rail, or ship-to-shore operations, this chassis ensures efficient and secure handling of cargo, contributing to the smooth flow of goods from origin to destination.

Gooseneck Design: The upward-curving gooseneck structure at the front end helps in evenly distributing the weight of the container, reducing stress on the chassis frame and improving overall stability during transportation.

Durable Construction: Made from high-strength steel, the chassis boasts a robust frame that can withstand heavy loads and harsh environmental conditions, ensuring a long service life.

Adjustable Locking Mechanisms: Equipped with adjustable twist locks that can accommodate different container sizes, providing a secure fit and preventing container movement during transit.

Lightweight Design: Despite its strength, the chassis is designed to be relatively lightweight, which helps in reducing fuel consumption when hauled by a tractor unit.

Corrosion Resistance: The surface is treated with anti-corrosion coatings to protect against rust and damage from exposure to moisture, salt, and other corrosive elements, common in port and coastal areas.

Easy Maintenance: Components are designed for easy access, simplifying routine maintenance and repair tasks, minimizing downtime.

Axles | 2 /3 Axles*13Ton,FUWA/BPW or Customization |

Loading Capacity | 30-80 Tons |

Container Chassis size | 12400* 2500*1570mm |

Material | Q345B,Beam Height:500mm,Upper Plate:14mm ,Bottom Plate:16mm,Middle:6mm |

Twist Lock | 8-12 Sets of 20/40ft container |

Braking System | Air Dual braking system,with relay valve |

Suspension | Reinforced mechanical Suspension,90mm*13mm*10 layers |

Landing gear | 28 Tons Two Speed |

Enhanced Maneuverability: The gooseneck design allows for a tighter turning radius compared to straight-frame chassis, making it easier to navigate in confined spaces such as ports and urban areas.

Increased Load Capacity: The robust steel construction and efficient weight distribution enable the chassis to handle heavy containers without compromising structural integrity.

Versatility: Compatible with a wide range of standard container sizes, eliminating the need for multiple chassis types, thus reducing the fleet size required by logistics companies.

Cost-Effective: The durable build and low maintenance requirements result in lower long-term operational costs, providing better value for money over the chassis's lifespan.

Improved Safety: Secure locking mechanisms and stable design reduce the risk of container shifts or falls during transportation, enhancing overall road safety and protecting both the cargo and other road users.

Intermodal Compatibility: Seamlessly integrates with different modes of transport, facilitating smooth transfers between truck, rail, and ship, making it an ideal choice for intermodal logistics operations.

Q: What container sizes can the Gooseneck Intermodal Skeleton Container Chassis accommodate?

A: It is designed to fit standard 20-foot, 40-foot, and 45-foot shipping containers, thanks to its adjustable locking mechanisms.

Q: What is the maximum weight capacity of this chassis?

A: The maximum weight capacity typically ranges from 40 to 50 tons, depending on the specific model and design specifications.

Q: How often does the chassis require maintenance?

A: Routine maintenance, such as checking twist locks, inspecting the frame for damage, and lubricating moving parts, is recommended every 3,000 to 5,000 miles, or as per the manufacturer's guidelines.

Q: Is the chassis compatible with all tractor units?

A: It is compatible with most standard tractor units that have the appropriate coupling system. However, it is advisable to check the compatibility with the specific tractor model before use.

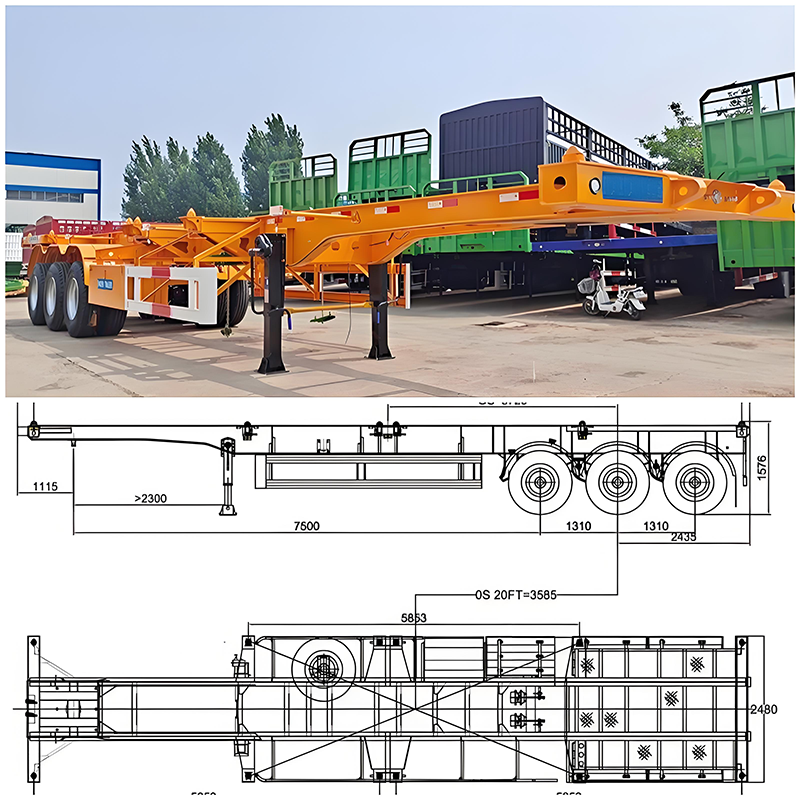

The Gooseneck Intermodal Skeleton Container Chassis is a specialized piece of transportation equipment engineered to facilitate the seamless movement of shipping containers across various intermodal transport networks. Its unique gooseneck design, which curves upward at the front, distinguishes it from other chassis types, allowing for optimal weight distribution and enhanced maneuverability. This chassis is widely utilized in ports, freight terminals, rail yards, and logistics centers, serving as a critical link in the global supply chain. It is compatible with standard shipping containers of multiple sizes, making it a versatile solution for businesses involved in international and domestic trade. Whether transporting containers via truck, rail, or ship-to-shore operations, this chassis ensures efficient and secure handling of cargo, contributing to the smooth flow of goods from origin to destination.

Gooseneck Design: The upward-curving gooseneck structure at the front end helps in evenly distributing the weight of the container, reducing stress on the chassis frame and improving overall stability during transportation.

Durable Construction: Made from high-strength steel, the chassis boasts a robust frame that can withstand heavy loads and harsh environmental conditions, ensuring a long service life.

Adjustable Locking Mechanisms: Equipped with adjustable twist locks that can accommodate different container sizes, providing a secure fit and preventing container movement during transit.

Lightweight Design: Despite its strength, the chassis is designed to be relatively lightweight, which helps in reducing fuel consumption when hauled by a tractor unit.

Corrosion Resistance: The surface is treated with anti-corrosion coatings to protect against rust and damage from exposure to moisture, salt, and other corrosive elements, common in port and coastal areas.

Easy Maintenance: Components are designed for easy access, simplifying routine maintenance and repair tasks, minimizing downtime.

Axles | 2 /3 Axles*13Ton,FUWA/BPW or Customization |

Loading Capacity | 30-80 Tons |

Container Chassis size | 12400* 2500*1570mm |

Material | Q345B,Beam Height:500mm,Upper Plate:14mm ,Bottom Plate:16mm,Middle:6mm |

Twist Lock | 8-12 Sets of 20/40ft container |

Braking System | Air Dual braking system,with relay valve |

Suspension | Reinforced mechanical Suspension,90mm*13mm*10 layers |

Landing gear | 28 Tons Two Speed |

Enhanced Maneuverability: The gooseneck design allows for a tighter turning radius compared to straight-frame chassis, making it easier to navigate in confined spaces such as ports and urban areas.

Increased Load Capacity: The robust steel construction and efficient weight distribution enable the chassis to handle heavy containers without compromising structural integrity.

Versatility: Compatible with a wide range of standard container sizes, eliminating the need for multiple chassis types, thus reducing the fleet size required by logistics companies.

Cost-Effective: The durable build and low maintenance requirements result in lower long-term operational costs, providing better value for money over the chassis's lifespan.

Improved Safety: Secure locking mechanisms and stable design reduce the risk of container shifts or falls during transportation, enhancing overall road safety and protecting both the cargo and other road users.

Intermodal Compatibility: Seamlessly integrates with different modes of transport, facilitating smooth transfers between truck, rail, and ship, making it an ideal choice for intermodal logistics operations.

Q: What container sizes can the Gooseneck Intermodal Skeleton Container Chassis accommodate?

A: It is designed to fit standard 20-foot, 40-foot, and 45-foot shipping containers, thanks to its adjustable locking mechanisms.

Q: What is the maximum weight capacity of this chassis?

A: The maximum weight capacity typically ranges from 40 to 50 tons, depending on the specific model and design specifications.

Q: How often does the chassis require maintenance?

A: Routine maintenance, such as checking twist locks, inspecting the frame for damage, and lubricating moving parts, is recommended every 3,000 to 5,000 miles, or as per the manufacturer's guidelines.

Q: Is the chassis compatible with all tractor units?

A: It is compatible with most standard tractor units that have the appropriate coupling system. However, it is advisable to check the compatibility with the specific tractor model before use.