| Availability: | |

|---|---|

| Quantity: | |

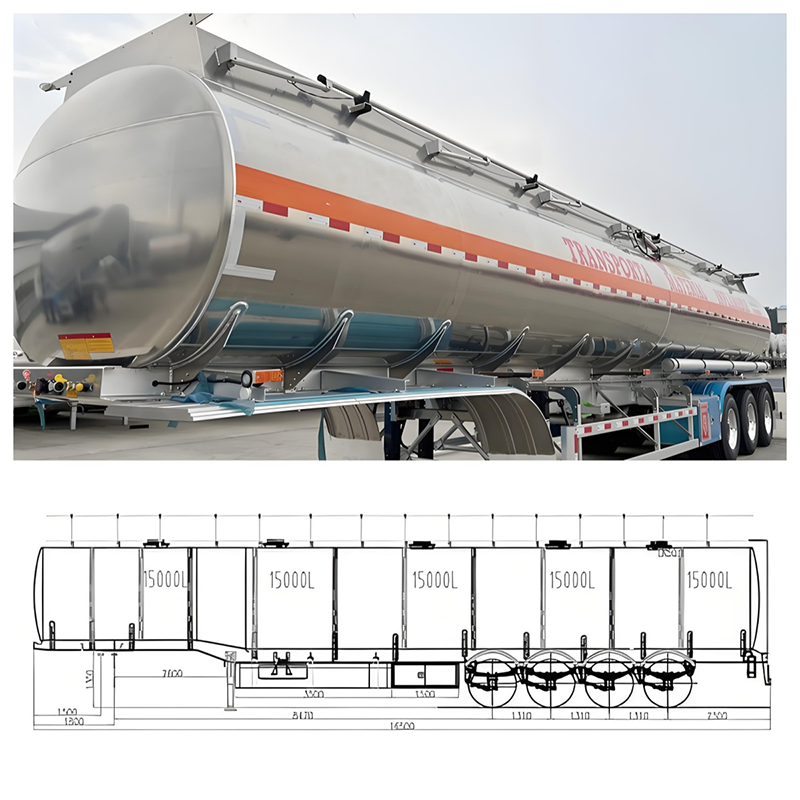

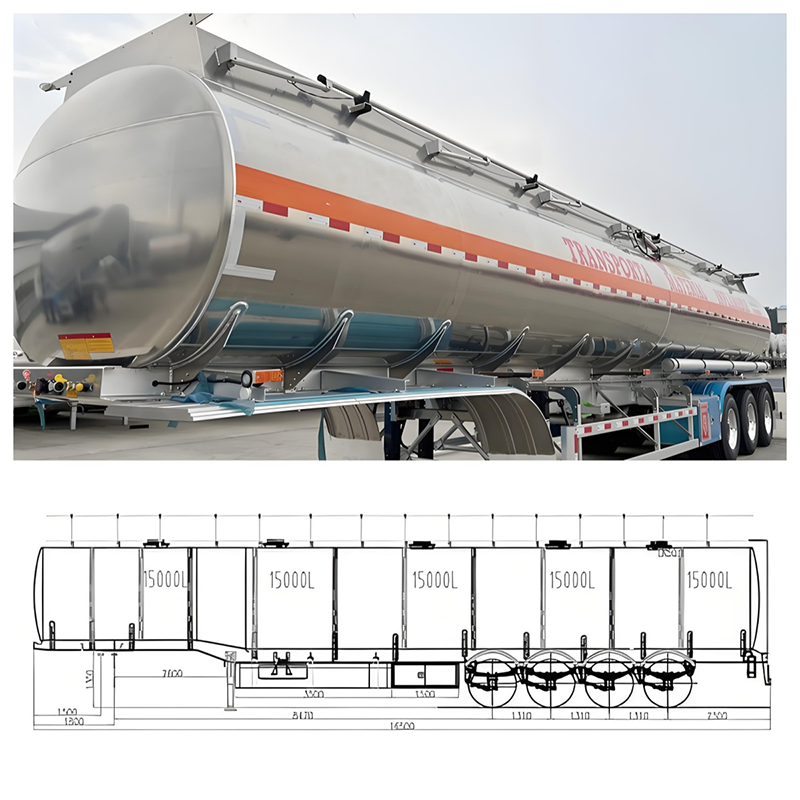

The Aluminum Chemical Tanker Semi Trailer is engineered for the secure and efficient transportation of diverse liquid chemicals. Constructed primarily from high-strength aluminum alloys, these trailers offer a significant weight reduction compared to steel alternatives while maintaining structural integrity and corrosion resistance essential for handling aggressive substances. They adhere to stringent international standards, including ADR/RID for hazardous materials transport. Typical capacities range from 30,000 to 45,000 liters, configurable to meet specific operational requirements.

Material Construction: Utilizes corrosion-resistant aluminum alloys (e.g., AA5083, AA5454) for the tank shell and critical components, ensuring longevity and reducing tare weight for increased payload capacity.

Compliance & Safety: Designed to meet or exceed ADR/RID, DOT 406, and TC regulations. Features include vapor recovery systems, bottom loading/unloading valves, pressure relief devices, and advanced emergency shut-off systems.

Compartmentalization: Often features multiple segregated compartments (e.g., 3-5) constructed with baffles or bulkheads. This allows simultaneous transport of different non-compatible chemicals and enhances stability.

Valving and Manways: Equipped with stainless steel or aluminum valves, fittings, and secure manways compatible with various chemical properties. Options include top or bottom loading configurations.

Subframe and Running Gear: Robust steel subframe supports the tank. Equipped with durable axles (air-suspension common), reliable braking systems (ABS standard), and suitable lighting.

This semi-trailer is indispensable for logistics companies servicing the chemical manufacturing, petrochemical, pharmaceutical, and agrochemical sectors. It safely transports a wide array of liquid chemicals, including corrosive acids (e.g., sulfuric acid), bases (e.g., caustic soda), solvents, alcohols, and other hazardous or non-hazardous liquids requiring specialized containment.

Q: What certifications do these trailers typically hold?

A: They are commonly built to ADR/RID (Europe), DOT 406 (USA), or TC (Canada) standards for hazardous materials transport. Certificates of conformity are provided.

Q: Can different compartments hold different chemicals simultaneously?

A: Yes, segregated compartments with individual discharge systems allow for the simultaneous transport of compatible but distinct chemicals, subject to regulatory approvals for the specific substances.

Q: How does aluminum construction benefit chemical transport?

A: Aluminum offers inherent corrosion resistance to many chemicals, reduces overall trailer weight for increased payload, and minimizes the risk of contamination compared to some steel types.

Q: What maintenance is specific to chemical tankers?

A: Regular internal and external inspections for corrosion or damage, thorough cleaning between loads (especially when changing chemicals), and meticulous maintenance of valves, seals, and safety devices are critical.

The Aluminum Chemical Tanker Semi Trailer is engineered for the secure and efficient transportation of diverse liquid chemicals. Constructed primarily from high-strength aluminum alloys, these trailers offer a significant weight reduction compared to steel alternatives while maintaining structural integrity and corrosion resistance essential for handling aggressive substances. They adhere to stringent international standards, including ADR/RID for hazardous materials transport. Typical capacities range from 30,000 to 45,000 liters, configurable to meet specific operational requirements.

Material Construction: Utilizes corrosion-resistant aluminum alloys (e.g., AA5083, AA5454) for the tank shell and critical components, ensuring longevity and reducing tare weight for increased payload capacity.

Compliance & Safety: Designed to meet or exceed ADR/RID, DOT 406, and TC regulations. Features include vapor recovery systems, bottom loading/unloading valves, pressure relief devices, and advanced emergency shut-off systems.

Compartmentalization: Often features multiple segregated compartments (e.g., 3-5) constructed with baffles or bulkheads. This allows simultaneous transport of different non-compatible chemicals and enhances stability.

Valving and Manways: Equipped with stainless steel or aluminum valves, fittings, and secure manways compatible with various chemical properties. Options include top or bottom loading configurations.

Subframe and Running Gear: Robust steel subframe supports the tank. Equipped with durable axles (air-suspension common), reliable braking systems (ABS standard), and suitable lighting.

This semi-trailer is indispensable for logistics companies servicing the chemical manufacturing, petrochemical, pharmaceutical, and agrochemical sectors. It safely transports a wide array of liquid chemicals, including corrosive acids (e.g., sulfuric acid), bases (e.g., caustic soda), solvents, alcohols, and other hazardous or non-hazardous liquids requiring specialized containment.

Q: What certifications do these trailers typically hold?

A: They are commonly built to ADR/RID (Europe), DOT 406 (USA), or TC (Canada) standards for hazardous materials transport. Certificates of conformity are provided.

Q: Can different compartments hold different chemicals simultaneously?

A: Yes, segregated compartments with individual discharge systems allow for the simultaneous transport of compatible but distinct chemicals, subject to regulatory approvals for the specific substances.

Q: How does aluminum construction benefit chemical transport?

A: Aluminum offers inherent corrosion resistance to many chemicals, reduces overall trailer weight for increased payload, and minimizes the risk of contamination compared to some steel types.

Q: What maintenance is specific to chemical tankers?

A: Regular internal and external inspections for corrosion or damage, thorough cleaning between loads (especially when changing chemicals), and meticulous maintenance of valves, seals, and safety devices are critical.