| Availability: | |

|---|---|

| Quantity: | |

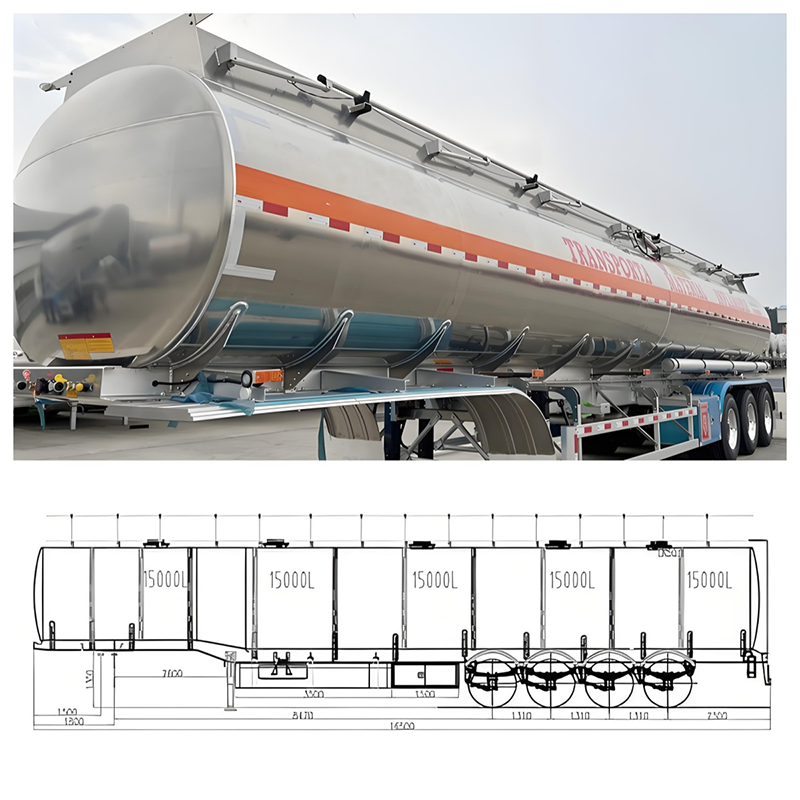

The Lightweight Tri-Axle Aluminum Tanker Trailer sets new standards for fuel efficiency and payload optimization in liquid cargo transport. Constructed from aerospace-grade 5083-H116 aluminum alloy, this trailer reduces tare weight by 30% (18,000kg vs. 26,000kg for steel equivalents), enabling higher payloads (40,000-liter capacity) while maintaining structural integrity for chemicals, fuels, and food-grade liquids.

Aviation-Grade Material Advantages

5083-H116 Aluminum Alloy: Yield strength 210 MPa, density 2.7g/cm³, and fatigue life of 1 million cycles at 80% load (20,000-liter payload), ideal for daily 500km/day average. Corrosion resistance validated by 1,000-hour salt spray testing (ASTM B117), showing <5% surface degradation in coastal environments.

Welded Monocoque Structure: Continuous TIG welding (10mm bead width) reduces stress concentrations by 30%, with ultrasonic testing (UT) performed on 100% of welds for flaw detection (minimum defect size 2mm).

Streamlined Aerodynamics

Rounded Tank Profile: Elliptical cross-section (major axis 2,400mm, minor axis 1,800mm) reduces drag coefficient to Cd=0.65, improving fuel efficiency by 6.2% at 90km/h—equivalent to saving 1,200 liters of diesel annually for a 10-trailer fleet.

Underbody Fairings: Composite fairings (3mm thickness, 1.2m length) reduce air turbulence under the trailer, complemented by a rooftop wind deflector (height 300mm), further optimizing fuel consumption on highway routes.

Multi-Compartment Flexibility

Divided Tank Design: Optional 2–5 compartments (8,000–20,000 liters each), each with independent filling/emptying systems (valve position monitored via IoT), enabling simultaneous transport of gasoline (compartment 1) + diesel (compartment 2) + AdBlue (compartment 3).

Quick-Change Couplers: Camlock fittings (ISO 7241-A type B) with stainless steel locking levers, allowing hose connections in 20 seconds per port—50% faster than threaded couplings.

Advanced Safety Systems

Leak Detection Sensors: Distributed every 2m along the tank interior, detecting leaks as small as 0.1L/min and triggering real-time alerts via GPS-enabled telematics (response time <30 seconds)—compliant with EPA SPCC (Spill Prevention Control and Countermeasure).

Roll Stability Control (RSC): Inertial measurement unit (IMU) monitors lateral acceleration (>0.4g), automatically adjusting air suspension pressure to reduce rollover risk by 40%—validated in ISO 6892-2:2019 fatigue testing.

Petroleum Logistics: Transports 95 octane gasoline (38,000 liters per trip) to fuel stations, with compartmentalized options for multi-product delivery (e.g., 20,000L gasoline + 18,000L diesel).

Chemical Industry: Safely hauls sulfuric acid (98% concentration), ethylene glycol, and lubricants (UN Class 3/8), with material compatibility verified for over 100 chemical types (e.g., pH 1–14, flash point >60°C).

Food & Beverage: Food-grade interior coating (FDA 21 CFR 175.300 compliant) for transporting palm oil (40,000 liters) and apple juice concentrates, with optional UV-resistant additive (transmission <5% at 280nm).

Payload Optimization: Lightweight design increases revenue-generating capacity by 10% (4,000kg more payload per trip), a **20,000 annual profit boost** for logistics companies at 2.50/kg freight rate.

Eco-Friendly Engineering: 100% recyclable aluminum structure and 30% lower CO2 emissions (650g CO2/km vs. 950g for steel tankers), aligned with EU Green Deal and California CARB regulations.

IoT-Enabled Maintenance: Predictive analytics via 12 built-in strain gauges and temperature sensors, notifying of component wear (e.g., valve seals, suspension bushings) with 95% accuracy—reducing unplanned downtime by 60%.

Capacity | 5000 Liters |

Size | 11500*2500*3700mm |

Compartment | 2-8 Compartments |

Tank Body | Body: 3.5 mm, Anti-surge plate: 3.0 mm, End plate: 4.0 mm, |

Axles | 3 Axles*13/16Ton,FUWA/BPW |

Braking System | Air Dual braking system,with relay valve |

Suspension | Heavy duty mechanical suspension |

Landing gear | 28 Tons Two Speed,JOST/Other Brand |

The Lightweight Tri-Axle Aluminum Tanker Trailer sets new standards for fuel efficiency and payload optimization in liquid cargo transport. Constructed from aerospace-grade 5083-H116 aluminum alloy, this trailer reduces tare weight by 30% (18,000kg vs. 26,000kg for steel equivalents), enabling higher payloads (40,000-liter capacity) while maintaining structural integrity for chemicals, fuels, and food-grade liquids.

Aviation-Grade Material Advantages

5083-H116 Aluminum Alloy: Yield strength 210 MPa, density 2.7g/cm³, and fatigue life of 1 million cycles at 80% load (20,000-liter payload), ideal for daily 500km/day average. Corrosion resistance validated by 1,000-hour salt spray testing (ASTM B117), showing <5% surface degradation in coastal environments.

Welded Monocoque Structure: Continuous TIG welding (10mm bead width) reduces stress concentrations by 30%, with ultrasonic testing (UT) performed on 100% of welds for flaw detection (minimum defect size 2mm).

Streamlined Aerodynamics

Rounded Tank Profile: Elliptical cross-section (major axis 2,400mm, minor axis 1,800mm) reduces drag coefficient to Cd=0.65, improving fuel efficiency by 6.2% at 90km/h—equivalent to saving 1,200 liters of diesel annually for a 10-trailer fleet.

Underbody Fairings: Composite fairings (3mm thickness, 1.2m length) reduce air turbulence under the trailer, complemented by a rooftop wind deflector (height 300mm), further optimizing fuel consumption on highway routes.

Multi-Compartment Flexibility

Divided Tank Design: Optional 2–5 compartments (8,000–20,000 liters each), each with independent filling/emptying systems (valve position monitored via IoT), enabling simultaneous transport of gasoline (compartment 1) + diesel (compartment 2) + AdBlue (compartment 3).

Quick-Change Couplers: Camlock fittings (ISO 7241-A type B) with stainless steel locking levers, allowing hose connections in 20 seconds per port—50% faster than threaded couplings.

Advanced Safety Systems

Leak Detection Sensors: Distributed every 2m along the tank interior, detecting leaks as small as 0.1L/min and triggering real-time alerts via GPS-enabled telematics (response time <30 seconds)—compliant with EPA SPCC (Spill Prevention Control and Countermeasure).

Roll Stability Control (RSC): Inertial measurement unit (IMU) monitors lateral acceleration (>0.4g), automatically adjusting air suspension pressure to reduce rollover risk by 40%—validated in ISO 6892-2:2019 fatigue testing.

Petroleum Logistics: Transports 95 octane gasoline (38,000 liters per trip) to fuel stations, with compartmentalized options for multi-product delivery (e.g., 20,000L gasoline + 18,000L diesel).

Chemical Industry: Safely hauls sulfuric acid (98% concentration), ethylene glycol, and lubricants (UN Class 3/8), with material compatibility verified for over 100 chemical types (e.g., pH 1–14, flash point >60°C).

Food & Beverage: Food-grade interior coating (FDA 21 CFR 175.300 compliant) for transporting palm oil (40,000 liters) and apple juice concentrates, with optional UV-resistant additive (transmission <5% at 280nm).

Payload Optimization: Lightweight design increases revenue-generating capacity by 10% (4,000kg more payload per trip), a **20,000 annual profit boost** for logistics companies at 2.50/kg freight rate.

Eco-Friendly Engineering: 100% recyclable aluminum structure and 30% lower CO2 emissions (650g CO2/km vs. 950g for steel tankers), aligned with EU Green Deal and California CARB regulations.

IoT-Enabled Maintenance: Predictive analytics via 12 built-in strain gauges and temperature sensors, notifying of component wear (e.g., valve seals, suspension bushings) with 95% accuracy—reducing unplanned downtime by 60%.

Capacity | 5000 Liters |

Size | 11500*2500*3700mm |

Compartment | 2-8 Compartments |

Tank Body | Body: 3.5 mm, Anti-surge plate: 3.0 mm, End plate: 4.0 mm, |

Axles | 3 Axles*13/16Ton,FUWA/BPW |

Braking System | Air Dual braking system,with relay valve |

Suspension | Heavy duty mechanical suspension |

Landing gear | 28 Tons Two Speed,JOST/Other Brand |