| Availability: | |

|---|---|

| Quantity: | |

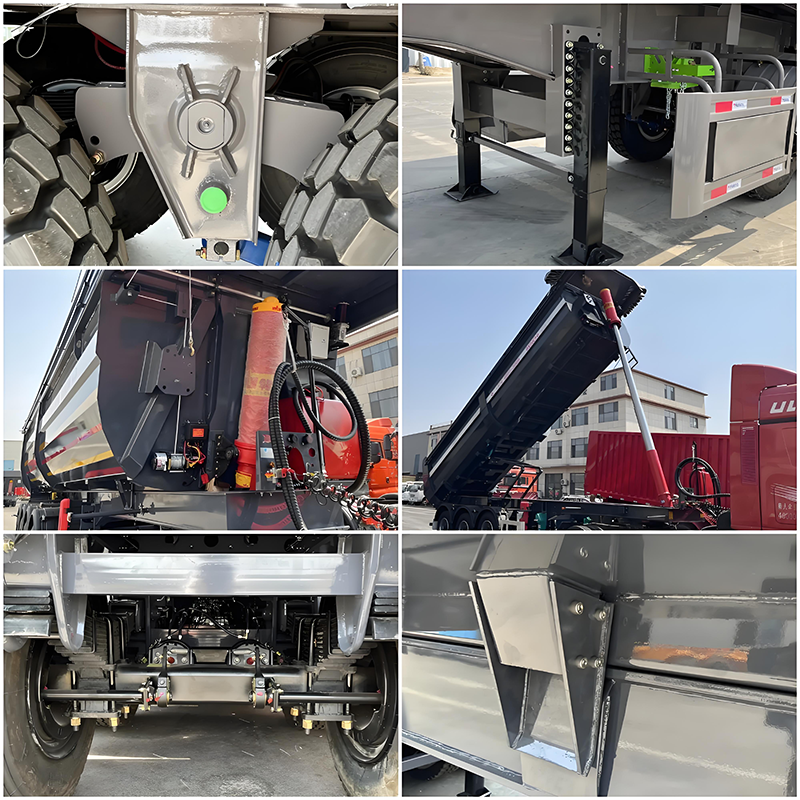

Our Heavy Duty Self Rear Dump Tipping Semi Trailers are engineered for efficient and reliable unloading of bulk materials in demanding applications. Featuring a robust chassis and a hydraulically powered tipping mechanism, these trailers allow the entire cargo box to pivot upwards from the rear, discharging the load behind the trailer. This self-contained dumping capability eliminates the need for external tipping mechanisms or specialized dump sites, making them indispensable in construction, mining, quarrying, agriculture, and waste management for transporting aggregates, soil, demolition debris, grain, and similar materials.

Bucket capacity | 45 cubic meters |

Axles | 5 Axles*13/16Ton,FUWA/BPW or Customization |

Lifting system | HYVA brand,FE/FC type cylinders,Diameter=214mm |

Dump semi trailer size | 11500*2500*3950mm |

Dump Box | T700 / Q345B double plate |

Material | Q345B,Beam Height:500mm,Upper Plate:14mm ,Bottom Plate:16mm,Middle:8mm |

Braking System | Air Dual braking system,with relay valve |

Suspension | Heavy duty mechanical suspension / Air bag / Bogies |

Landing gear | 28 Tons Two Speed |

Reinforced Chassis & Body: Constructed with high-tensile steel for the chassis and often wear-resistant steel (e.g., Hardox or equivalent) for the body, ensuring longevity under abrasive loads and high-impact conditions.

High-Capacity Hydraulic System: Equipped with powerful, synchronized hydraulic cylinders (typically two or more) capable of generating substantial lifting force to efficiently tip loads, even when packed or wet. Systems include reliable pumps, valves, and reservoirs.

Durable Tipping Mechanism: Features heavy-duty pivot points (kingpins), reinforced hinge assemblies, and robust subframes designed to withstand the stresses of repeated tipping cycles over years of service.

Enhanced Safety Systems: Incorporates safety props or latches to securely hold the body in the raised position during maintenance, along with hydraulic system safeguards to prevent accidental lowering.

Functional Body Design: Offers various body styles (e.g., rock, coal, grain) with optional features like tailgates (manual or hydraulic), liners for material release, and aerodynamic headboards.

Operational Efficiency: Rapid unloading capability significantly reduces cycle times compared to manual unloading or trailers requiring fixed tipping ramps, boosting fleet productivity.

Versatile Site Access: The self-contained nature allows dumping virtually anywhere with sufficient overhead clearance, providing flexibility on diverse job sites without reliance on specific infrastructure.

High Payload Volume: Designed to maximize legal cubic capacity, optimizing the volume of material transported per trip and reducing the number of journeys required.

Material Discharge Control: The rear-dump design provides good control over the placement of the discharged material pile, beneficial for precise filling or spreading tasks.

Reduced Operational Costs: Durable construction minimizes downtime for repairs, while efficient unloading saves fuel and labor costs associated with alternative unloading methods.

What is the typical lifting capacity of the hydraulic system?

Hydraulic systems are sized according to the trailer's payload rating and body size, commonly ranging from 40 to over 100 tons lifting capacity. Exact specifications depend on the model and customer requirements.

How long does it take to fully tip the load?

Dump cycle times vary based on load weight, material type, and hydraulic system power, but typically range between 30 seconds to 2 minutes for a full lift, tip, and lower sequence.

What maintenance does the hydraulic system require?

Regular maintenance includes checking hydraulic fluid levels and condition, inspecting hoses and fittings for leaks or wear, ensuring cylinder rods are clean and undamaged, and periodic fluid changes as per the manufacturer's schedule.

Can these trailers handle cohesive or wet materials?

Yes, the powerful hydraulic systems are designed to handle packed or damp materials. Optional body liners (e.g., UHMW polyethylene) can be added to improve material release, especially for sticky substances like wet clay or certain waste materials.

Are different body heights and lengths available?

Yes, we offer various body dimensions to optimize capacity within legal height and length constraints for different regions and material densities. Options include standard, high-side, and extra-high-side configurations.

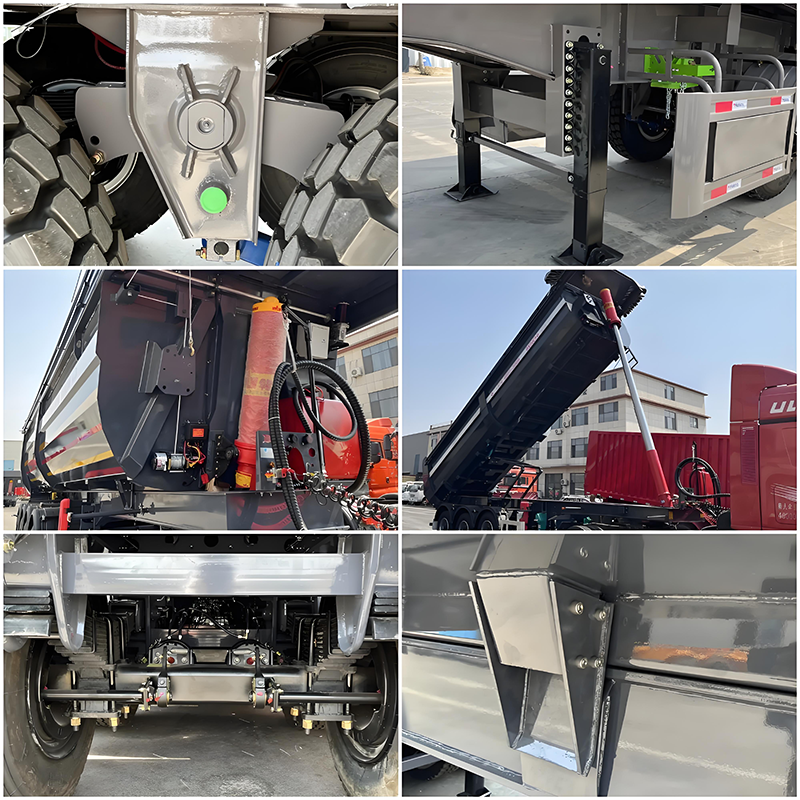

Our Heavy Duty Self Rear Dump Tipping Semi Trailers are engineered for efficient and reliable unloading of bulk materials in demanding applications. Featuring a robust chassis and a hydraulically powered tipping mechanism, these trailers allow the entire cargo box to pivot upwards from the rear, discharging the load behind the trailer. This self-contained dumping capability eliminates the need for external tipping mechanisms or specialized dump sites, making them indispensable in construction, mining, quarrying, agriculture, and waste management for transporting aggregates, soil, demolition debris, grain, and similar materials.

Bucket capacity | 45 cubic meters |

Axles | 5 Axles*13/16Ton,FUWA/BPW or Customization |

Lifting system | HYVA brand,FE/FC type cylinders,Diameter=214mm |

Dump semi trailer size | 11500*2500*3950mm |

Dump Box | T700 / Q345B double plate |

Material | Q345B,Beam Height:500mm,Upper Plate:14mm ,Bottom Plate:16mm,Middle:8mm |

Braking System | Air Dual braking system,with relay valve |

Suspension | Heavy duty mechanical suspension / Air bag / Bogies |

Landing gear | 28 Tons Two Speed |

Reinforced Chassis & Body: Constructed with high-tensile steel for the chassis and often wear-resistant steel (e.g., Hardox or equivalent) for the body, ensuring longevity under abrasive loads and high-impact conditions.

High-Capacity Hydraulic System: Equipped with powerful, synchronized hydraulic cylinders (typically two or more) capable of generating substantial lifting force to efficiently tip loads, even when packed or wet. Systems include reliable pumps, valves, and reservoirs.

Durable Tipping Mechanism: Features heavy-duty pivot points (kingpins), reinforced hinge assemblies, and robust subframes designed to withstand the stresses of repeated tipping cycles over years of service.

Enhanced Safety Systems: Incorporates safety props or latches to securely hold the body in the raised position during maintenance, along with hydraulic system safeguards to prevent accidental lowering.

Functional Body Design: Offers various body styles (e.g., rock, coal, grain) with optional features like tailgates (manual or hydraulic), liners for material release, and aerodynamic headboards.

Operational Efficiency: Rapid unloading capability significantly reduces cycle times compared to manual unloading or trailers requiring fixed tipping ramps, boosting fleet productivity.

Versatile Site Access: The self-contained nature allows dumping virtually anywhere with sufficient overhead clearance, providing flexibility on diverse job sites without reliance on specific infrastructure.

High Payload Volume: Designed to maximize legal cubic capacity, optimizing the volume of material transported per trip and reducing the number of journeys required.

Material Discharge Control: The rear-dump design provides good control over the placement of the discharged material pile, beneficial for precise filling or spreading tasks.

Reduced Operational Costs: Durable construction minimizes downtime for repairs, while efficient unloading saves fuel and labor costs associated with alternative unloading methods.

What is the typical lifting capacity of the hydraulic system?

Hydraulic systems are sized according to the trailer's payload rating and body size, commonly ranging from 40 to over 100 tons lifting capacity. Exact specifications depend on the model and customer requirements.

How long does it take to fully tip the load?

Dump cycle times vary based on load weight, material type, and hydraulic system power, but typically range between 30 seconds to 2 minutes for a full lift, tip, and lower sequence.

What maintenance does the hydraulic system require?

Regular maintenance includes checking hydraulic fluid levels and condition, inspecting hoses and fittings for leaks or wear, ensuring cylinder rods are clean and undamaged, and periodic fluid changes as per the manufacturer's schedule.

Can these trailers handle cohesive or wet materials?

Yes, the powerful hydraulic systems are designed to handle packed or damp materials. Optional body liners (e.g., UHMW polyethylene) can be added to improve material release, especially for sticky substances like wet clay or certain waste materials.

Are different body heights and lengths available?

Yes, we offer various body dimensions to optimize capacity within legal height and length constraints for different regions and material densities. Options include standard, high-side, and extra-high-side configurations.